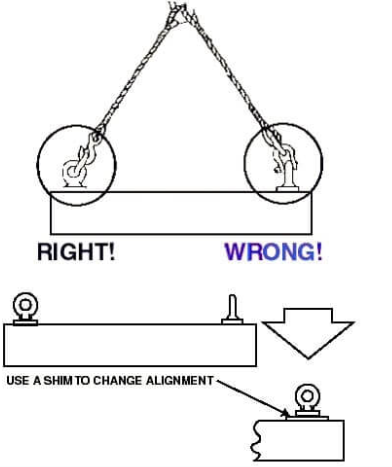

Eye bolts in electrical panels are special bolts that have a round loop (called an “eye”) at one end and screw threads at the other end. They get screwed tightly into the metal frame or mounting plate inside the electrical panel.

The main job of these eye bolts is to provide safe places to attach ropes, chains, slings, cranes, or hoists when you need to lift, move, or position heavy electrical panels. Electrical panels can weigh hundreds or even thousands of kilograms, so eye bolts make it safe to handle them during installation, maintenance work, or when relocating the panels to a new location.

Usually, you find 2-4 eye bolts installed at the top corners of the panel frame, so the weight is balanced properly when lifting.

Purpose of Eye Bolts in Electrical Panels

Eye bolts fulfill several essential safety and handling functions:

- Safe Lifting: Primary attachment points for cranes, hoists, or slings when lifting complete panels (200–2000+ kg).

- Panel Positioning: Guide panels into position using ropes or come-alongs during installation.

- Temporary Anchoring: Secure panels to transport frames, scaffolding, or lifting beams.

- Emergency Retrieval: Access points for rescue operations in hazardous locations.

Types of Eye Bolts Used in Panels

| Type | Features | Panel Application |

|---|---|---|

| Drop-Forged Eye Bolts | High-strength forged steel, welded-free eye | Heavy panels (>500 kg), permanent installation |

| Shoulder Eye Bolts | Integral shoulder prevents thread pull-out | Angular loads, frequent lifting |

| Machinery Eye Bolts | Heavy-duty, larger eyes for slings | Large MCCs, VFD panels, switchgear |

| Lag Eye Bolts | Wood screw threads | Temporary wooden transport cradles |

| Collared Eye Bolts | Flange under eye for angular loads | Side lifting, tilted positioning |

Common Applications

- Control Panels: PLC, DCS marshalling cabinets

- Power Distribution: MCCBs, ACBs, metering panels

- Motor Control Centers: VFDs, soft starters

- Switchgear: HV/LV cubicles, ring main units

Eye bolts are simple but critical safety hardware that prevent accidents during panel handling. Proper selection, installation, and inspection ensure safe lifting operations throughout the panel lifecycle

Leave a Reply