A chiller is a cooling system that removes heat from a liquid (typically water) to provide reliable temperature control for buildings and industrial processes. Whether you’re in a comfortable office building or enjoying a cold beverage, chillers likely play a critical role behind the scenes.

How Chillers Work: The Cooling Process

Chillers operate using a refrigeration cycle that transfers heat from one place to another. In simple terms, they absorb heat from water and reject it elsewhere. The cooling process follows these key steps:

- Warm water enters the evaporator from the building or process

- Inside the evaporator, heat transfers from the water to a refrigerant

- The refrigerant evaporates as it absorbs this heat

- The compressor pressurizes the refrigerant gas, raising its temperature

- The hot refrigerant moves to the condenser where it releases heat

- The refrigerant condenses back to liquid form

- An expansion device reduces the refrigerant’s pressure

- The cycle repeats continuously.

This continuous cycle keeps removing heat from your building or equipment, maintaining optimal temperatures.

Key Components of a Chiller System

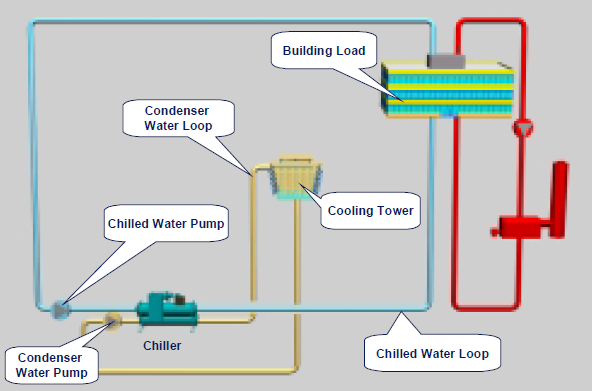

As shown in the diagram, a water-cooled chiller system consists of:

- Chiller Unit: The main cooling equipment containing the refrigeration components

- Chilled Water Pump: Circulates cooled water to the building

- Condenser Water Pump: Moves water between the condenser and cooling tower

- Cooling Tower: Releases heat from the system to the outside air

- Condenser Water Loop: Carries heat away from the chiller

- Chilled Water Loop: Delivers cooled water to air handlers in the building.

Types of Chillers

The chiller can be water-cooled, air-cooled, or evaporatively cooled:

- Water-cooled chillers use cooling towers to reject heat and are more efficient but require water treatment

- Air-cooled chillers reject heat directly to the surrounding air, requiring no water treatment but typically consuming more energy

- Evaporatively cooled chillers combine features of both types

Compressor Types

Chillers use one of four main compressor types:

- Reciprocating compressors: Suitable for smaller systems and peak loads

- Scroll compressors: Efficient for medium-sized applications

- Screw compressors: Can handle high compression ratios efficiently

- Centrifugal compressors: Most efficient at peak loads for larger applications

Leave a Reply