A motor disconnector switch serves as a vital component in ensuring the safe disconnection of a motor from its power source, facilitating maintenance or safety procedures. Motors are indispensable devices in numerous applications, ranging from simple fans to large-scale wind turbine fans, due to their ability to facilitate linear or rotational movement in various processes.

However, many are unaware of the motor disconnector switch, a device that acts as a switch to provide power to the motor.

The motor disconnector switch plays a crucial role in enhancing worker safety, minimizing downtime, and providing the flexibility to isolate a motor from the circuit when not in use. Understanding the concept of a motor disconnector switch is essential for electrical engineers and technicians alike

Table of Contents

5 Purpose of Using a Motor Disconnector Switch

Consider a scenario where a motor operates in either auto or manual mode. In the event of a PLC failure, operators may resort to manual mode control, potentially posing risks if an unintended start occurs. In such situations, the operator’s safety near the motor could be compromised, emphasizing the importance of isolating the motor solely from operation. This is where the motor disconnector switch proves invaluable.

The primary purpose of this switch is to isolate the motor connection as needed and reintegrate it into the system once maintenance work is completed, thereby mitigating the risk of accidents involving live power exposure.

Functionality of a Motor Disconnector Switch

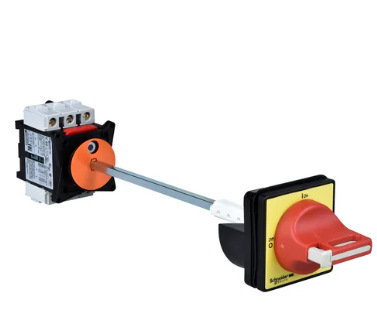

The motor disconnector switch comprises a contact mechanism manipulated by the technician to control the power supply. Typically, this contact takes the form of a handle or toggle switch. Positioned within an enclosure, the switch prevents operators from direct contact with live wires, enhancing safety measures. The switch’s handle interfaces with a rod-type connection to the contactor inside the panel, regulating the motor’s power supply accordingly.

Installation methods are critical, as they dictate the operator’s ability to manipulate the motor without direct contact with internal electrical components. The switch’s integration with a contactor ensures that the motor remains inoperative regardless of its mode, enhancing safety protocols.

Types of Motor Disconnector Switches

Various types of motor disconnector switches cater to diverse industrial requirements, including fused and non-fused options, rotary switches, knife switches, safety switches, magnetic switches, circuit breakers, and push-button or toggle switches.

Factors for Selecting a Motor Disconnector Switch

When selecting a motor disconnector switch, several factors merit consideration:

- Current rating compatibility with motor requirements.

- Space constraints within the panel.

- Compliance with industry standards and certifications.

- Smooth handle operation.

- Resistance to environmental and chemical factors.

By carefully assessing these factors, users can ensure the optimal performance and safety of their motor disconnector switches in diverse industrial settings.

Leave a Reply